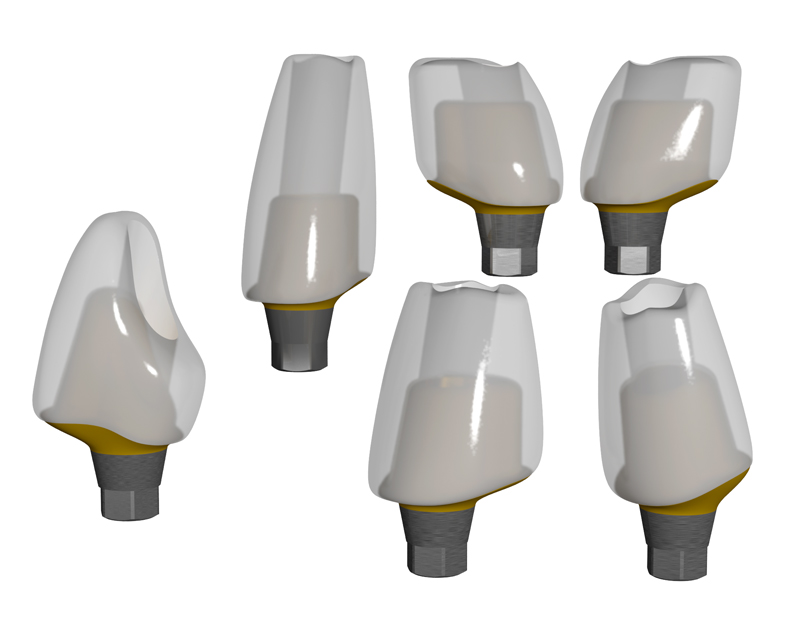

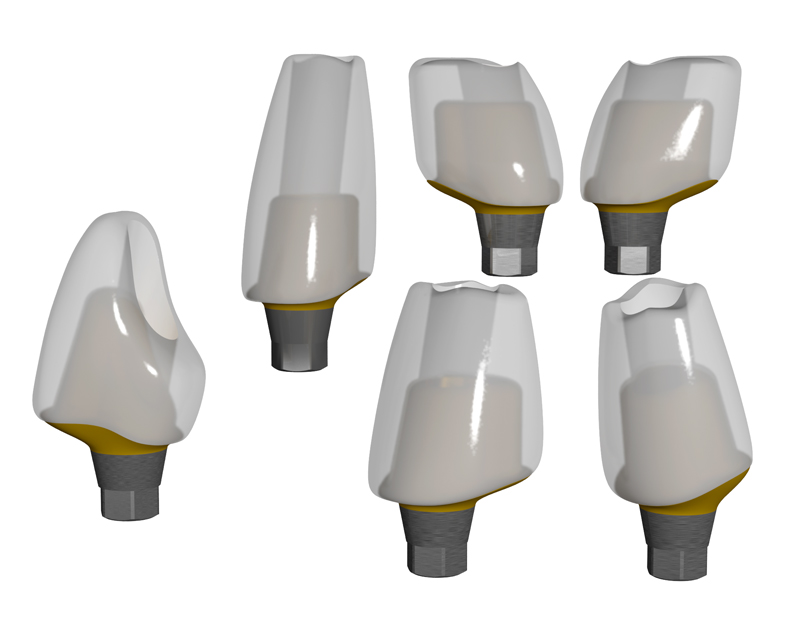

Six basic shapes suitable for all teeth

With our LTS-BASE® products, even the most difficult cases are easy to solve. Abutments4life® offers you an universal product line of high quality accessories which have all been new developed.

Anteriors

LTS hybrid adhesive base developed especially for the front tooth region considering an emergence profile at palatal implant position. She shows the above mentioned characteristics. The screw access channel is displaced palatally. For this reason the incisal edge is not broken through and the risk of a ceramic crown to break is considerably reduced.

Premolars

LTS hybrid adhesive base for the premolar area – and against orally at 11° angulated screw access channel and two stabilizing grooves. The adhesive surface is 5 mm high and may be securely bevelled up to 40°.

Premolars mesial angulated 1/3

LTS hybrid adhesive base for the premolar area – and against orally at 11° angulated screw access channel and two stabilizing grooves. The adhesive surface is 5 mm high and may be securely bevelled up to 40°.

Premolar mesial angulated 2/4

This adhesive base is designated for the use in the upper left and lower right quadrant.

Molars

LTS hybrid adhesive base for the molar region and against orally at 11° angulated screw access. This is designed for the provision of wider gaps at a reduced number of implants and if the available bone material is insufficient. A lateral screw may be fitted. The angulation facilitates the screw access channel to come right in the middle below the fissure.

Molar Inverse (LJ)

LTS hybrid adhesive base for the molar region and against orally at 11° angulated screw access. This is designed for the provision of wider gaps at a reduced number of implants and if the available bone material is insufficient. A lateral screw may be fitted. The angulation facilitates the screw access channel to come right in the middle below the fissure.

Standard S&L

LTS adhesive base for hybrid abutments without angulation but with an improved inner geometry and changed anti-rotation protection.

The forces acting in the adhesive base could be reduced to values significantly below the yield strength of titanium by the use of conical screw design.

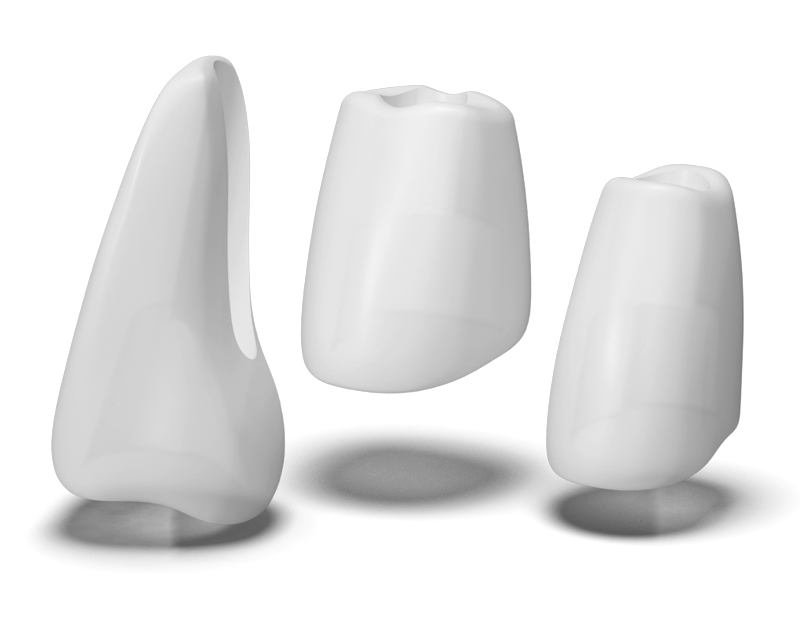

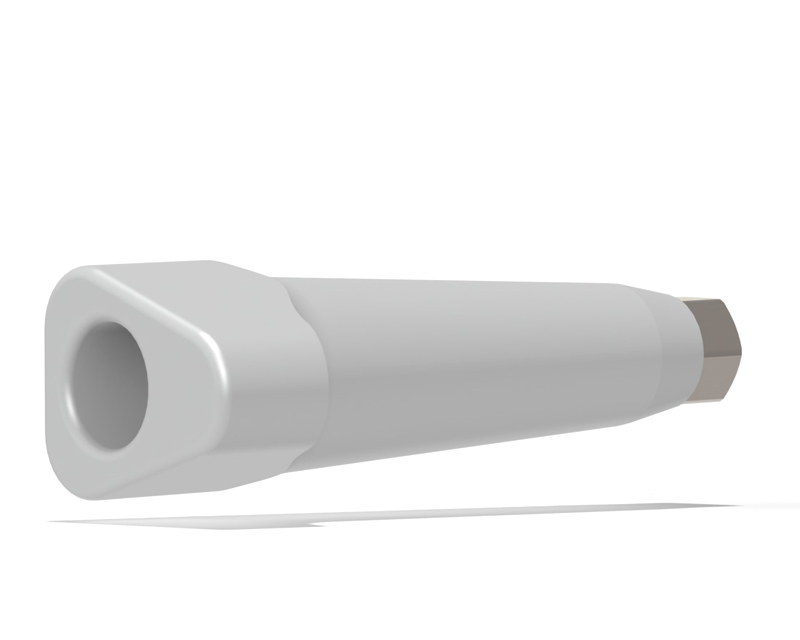

Healingcaps / Gingivaformers

The healing caps are shaped three-dimensional and made of bio compatible PEEK. They can be adapted individual to the mucosa as required. Especially long-term stable emergence profile and oral implant positioning are under considering of actual scientific findings.

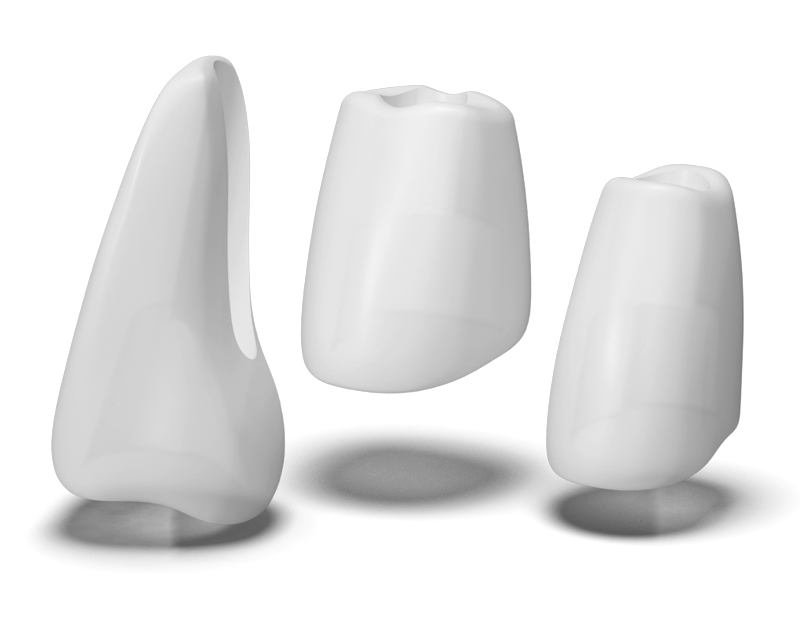

Prefabricated adhesive bodies

LTS-BASE® offers standardized and prefabricated adhesive bodies for sale. They are available in different materials such as zirconium, lithium disilicate glass-ceramics, PEEK or wax. Furthermore, the adhesive bodies are available in defferent sizes, designs and forms.

Screws

The forces acting in the adhesive base could be reduced to values significantly below the yield strength of titanium by the use of conical screw design.

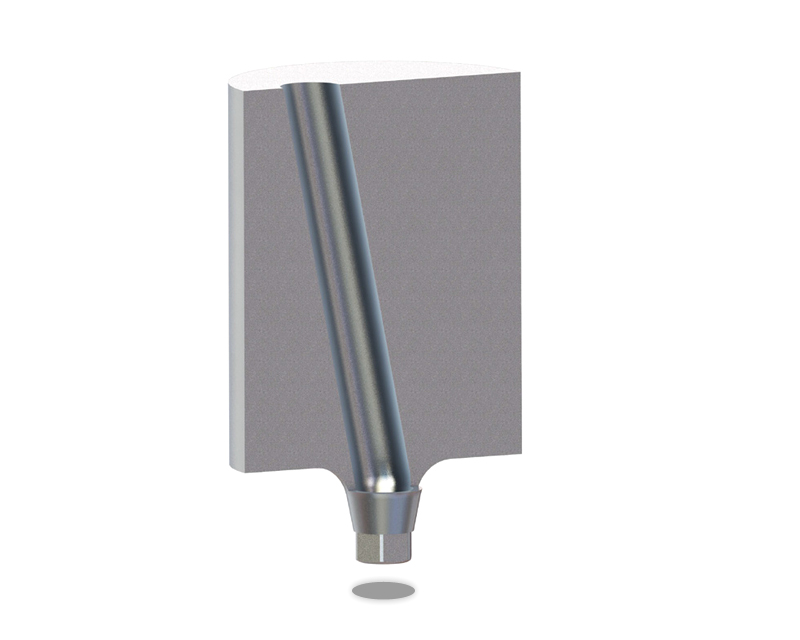

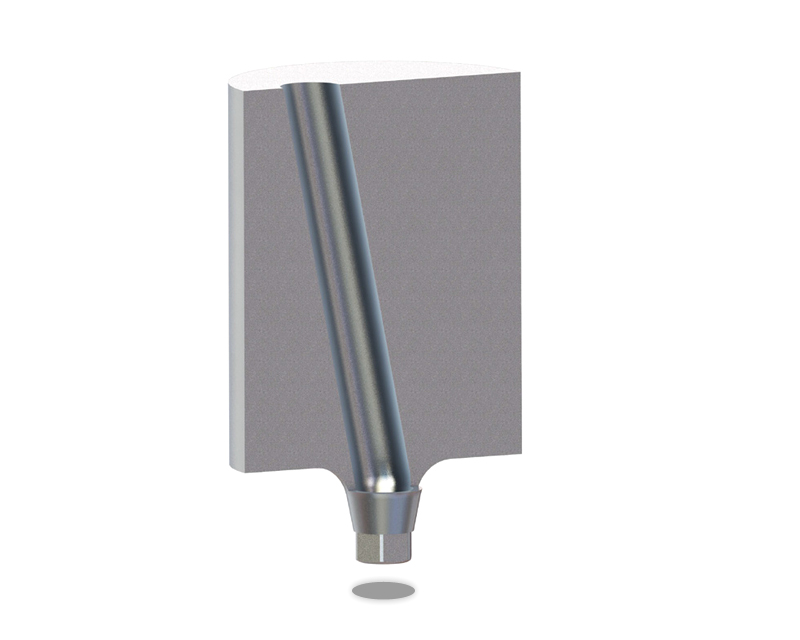

Pre-milled blankets with implant-interface

Abutments4life® supplies commercial customers having appropriate hardware equipment with milling blankets with angulated screw access channel of best material quality.

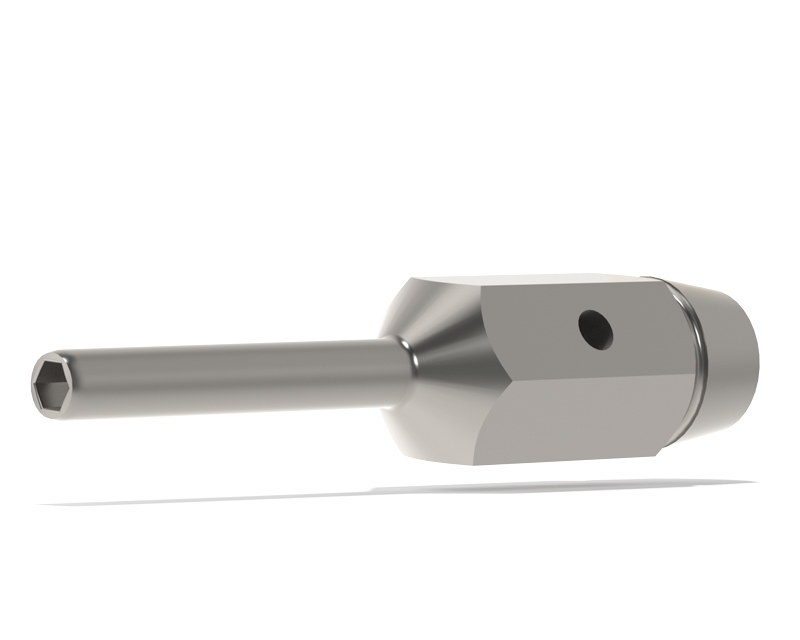

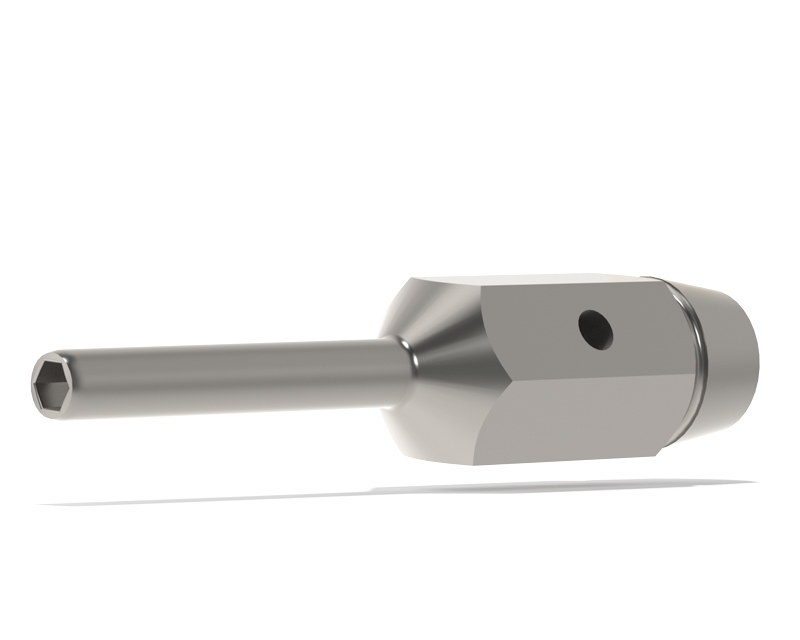

Socket wrench

Our wrench sockets and drivers ISO shaft for angled handpieces are standardised and may be used in almost every common system.

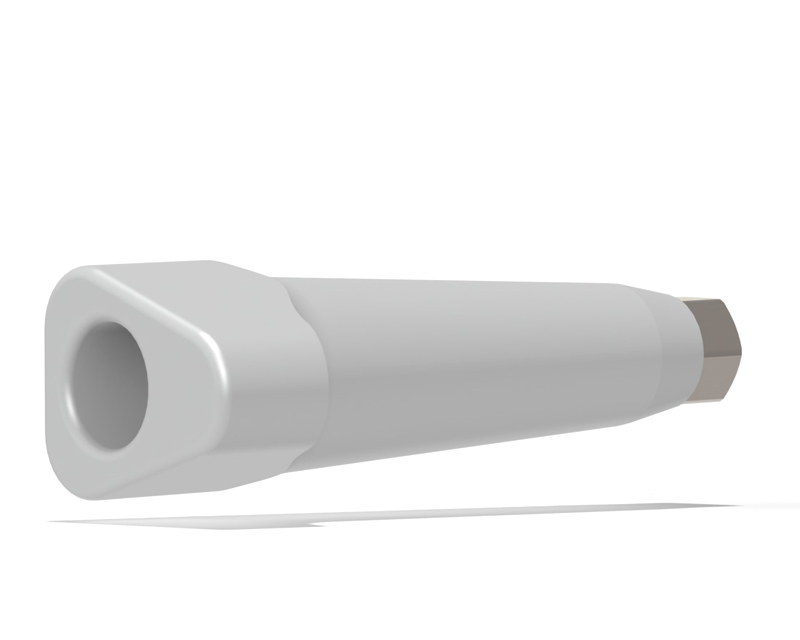

Scanbody

The scanbody was developed in cooperation with the manufacturers of the digitizers. It is especially slim, reflection-optimized and has marks enabling the user to do a better matching

Product line of hybrid abutments

The hybrid abutments from LTS-BASE® combine the positive properties of titanium abutments and full ceramic abutments. For each Abutment in the Product range are custom-made adhesive bodies available. Compatible to all current implant systems.

Connection geometry for all current implant systems